| Made in the USA

Clients

We Serve

| Made in the USA

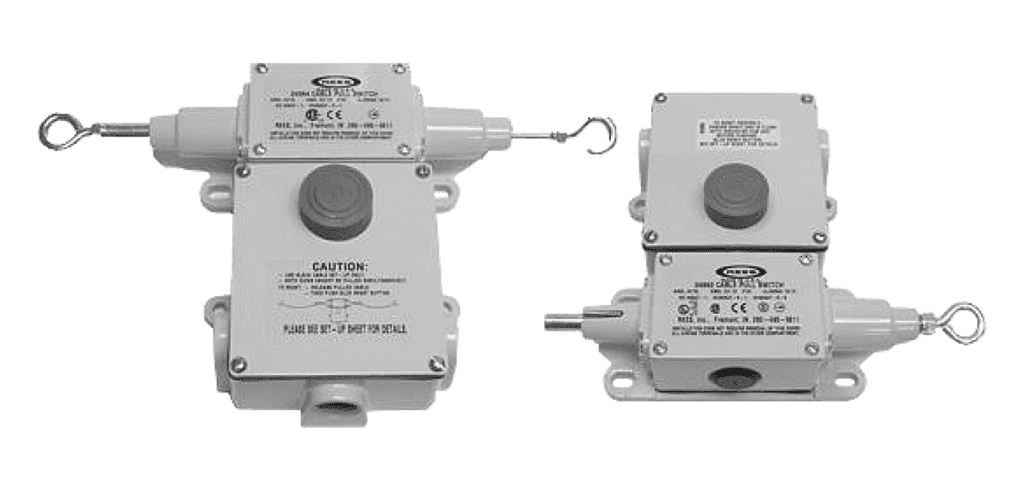

OUR NEWEST OFFERING:

INLINE SWITCHES

La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.

| Made in the USA

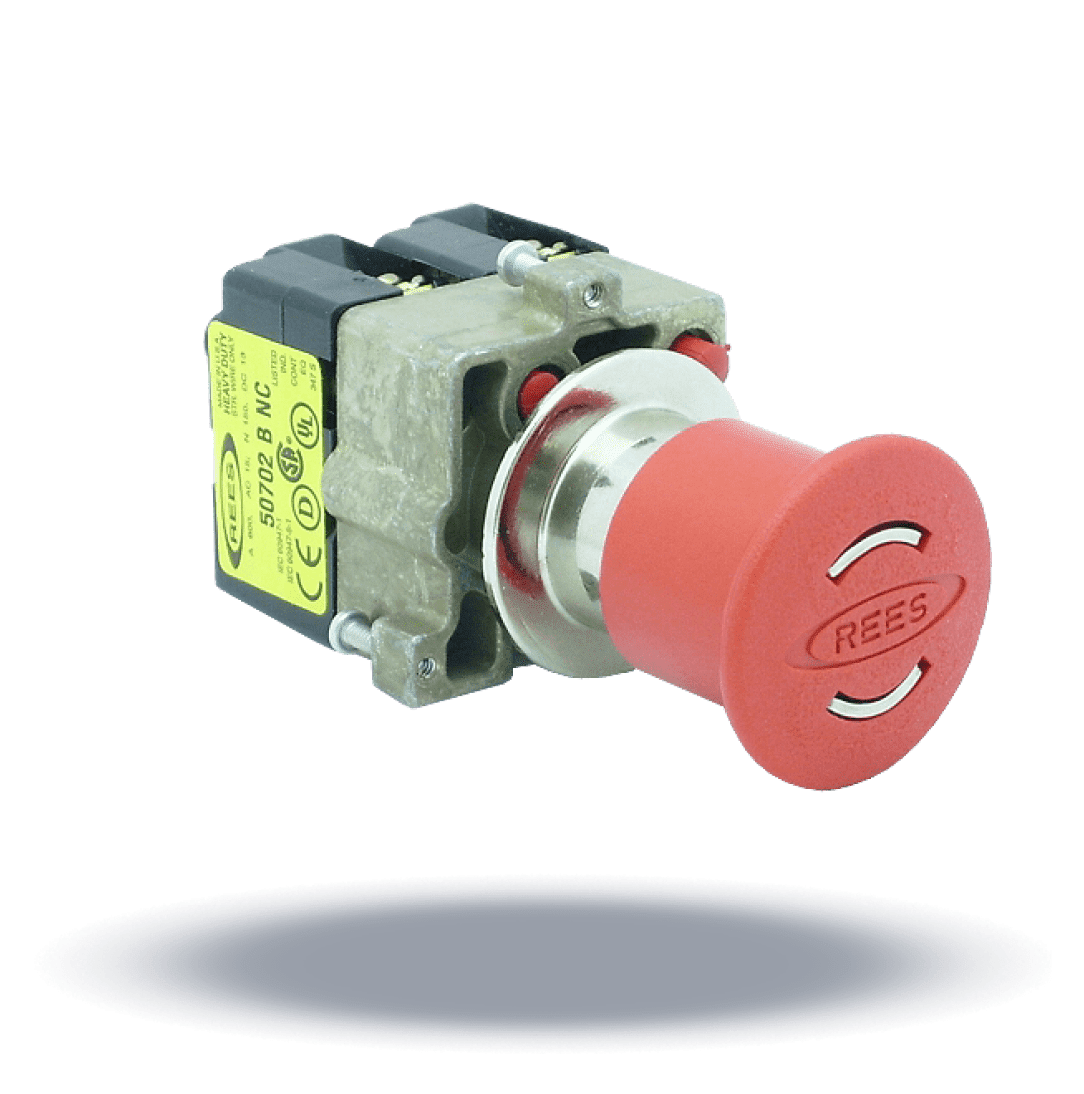

EXPLORE OUR 30.5 MM PUSH BUTTONS

La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.

| Made in the USA

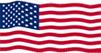

MANUFACTURER OF ELECTROMECHANICAL INDUSTRIAL CONTROL SWITCHES

La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.

| Made in the USA

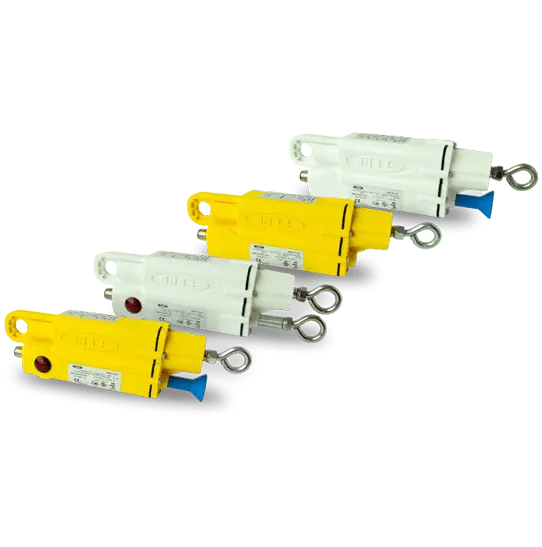

FIND OUT HOW OUR CABLE SWITCHES CAN BENEFIT YOUR BUSINESS

La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.

| Made in the USA

CHECK OUT OUR SINGLE PLUNGER PUSH BUTTONS

La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.

| Made in the USA

22.5 MM PUSH BUTTONS WITH VARIOUS FEATURES

La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.La salud es nuestra misión. Encárguese de la acción, nosotros lo abastecemos, nosotros lo respandamos.

Previous

Next

our PRODUCTS

Made in the USA

DOWNLOAD OUR

brochure

Discover everything you need to know about our comprehensive list of products!

REES Since 1929

Download our Brochure

Download our Brochure

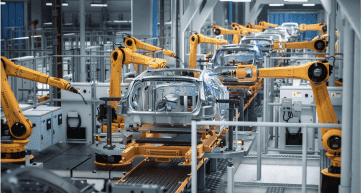

Automotive

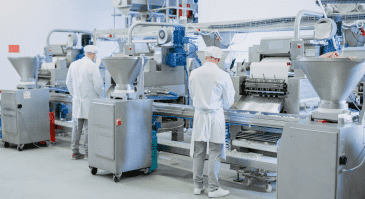

Food Processing

Conveyor

Material Handling

Stamping

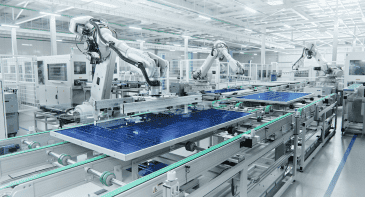

Automation

Previous

Next

INDUSTRIES

SERVED

We are proud to serve such industries as:

Automotive, Conveyor, Material Handling, Food Processing, Automation and Many More…

Rees products are what we use on our equipment. The best we've ever had. Just one example is a Rees palm button that’s on our punch press machine. It lasted 30 years before we needed to replace it. (It’s quality AND made in the USA ) I highly recommend Rees Products.

ReyDayton Superior

I just wish we could do more business with REES.

ChrisControl Center

Very convenient to use REES for my needs.

Bill Crescent Electric

I am a distributor and have had no issues on my end or from my customers.

CaseyCBT Company

REES is one of our best manufacturers.

LindaBecker Electric

High quality, heavy duty switch operators.

DannySantee Cooper

The customer service team is always very helpful.

Jody MillsThe Reynolds Company

I find it very convenient and expeditious ordering parts through your website, rarely needing any in-person help. But when I do it's always been excellent.

KevinC&W Services

I have been using Rees buttons and switches for years and I think they're the best out there.

JohnIroquois Industries

The Rees electrical controls that we purchased to upgrade our Stamping Presses perform very well. Rees is our preferred manufacturer for our electrical control needs. Our Industrial Maintenance and Engineering staff know about Rees' reputation for reliable and durable products, and request Rees whenever we are in need of more electrical controls.

ScottB. Walter & Co.

Previous

Next

about rees inc.

Rees Inc. offers a wide selection of cable and rope pull switches designed and built to withstand rugged industrial plant environments. Vinyl covered aircraft cable, indicator lights, and various accessory items are also available. Rees Inc. also offers lockable emergency stop switches, push-button operators, ergonomic palm buttons, double plunger start-stop switches, and many complimentary accessories such as legend plates, ring guards, and pilot lights.

A LEADER IN THE DESIGN OF CONTROL SWITCHES SINCE 1929